BUILDING SYSTEMS

PRESTRESSED

HOLLOW-CORE SLAB SYSTEM

HALLOWCORE SLAB SYSTEMS

Method of Manufacturing

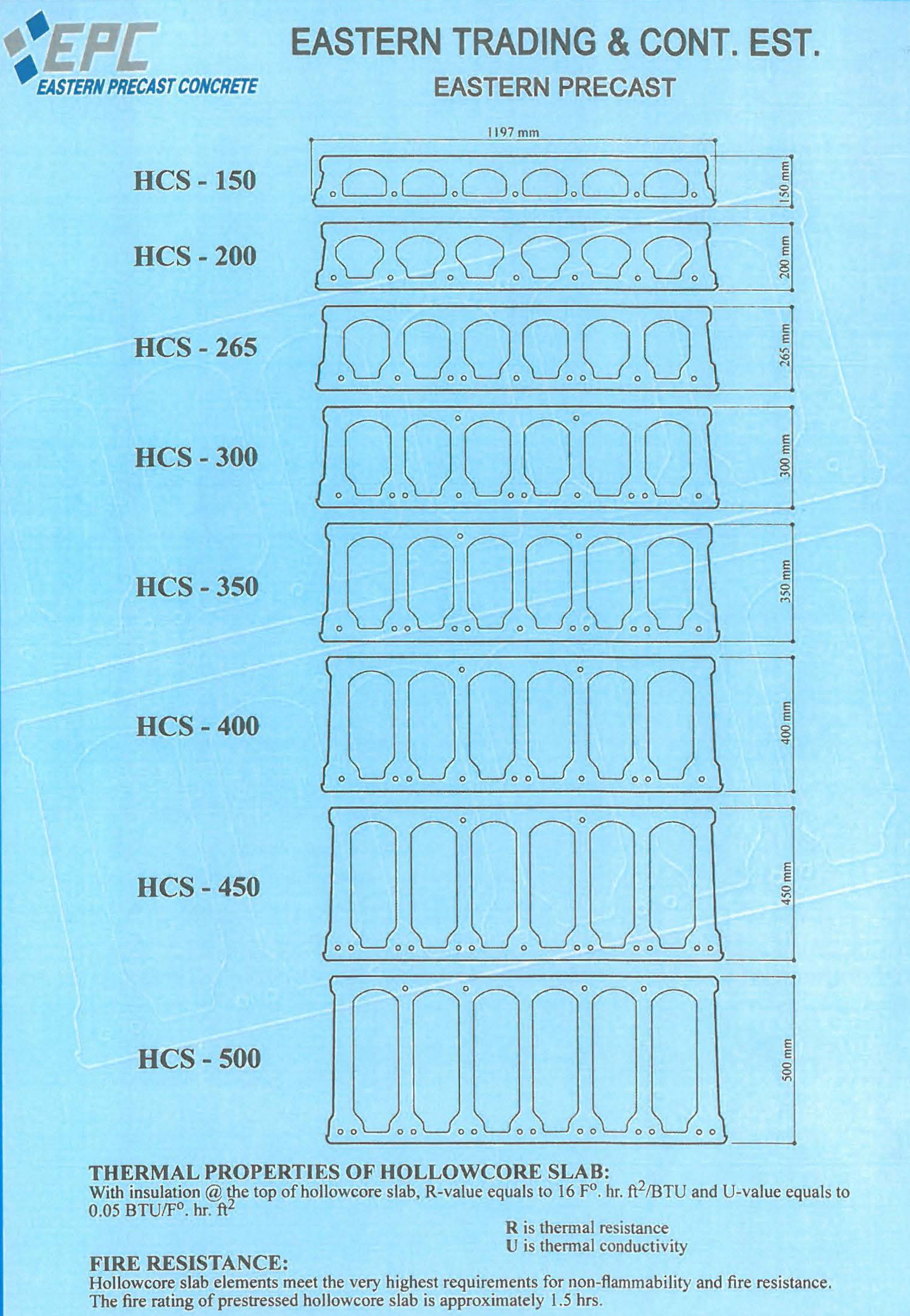

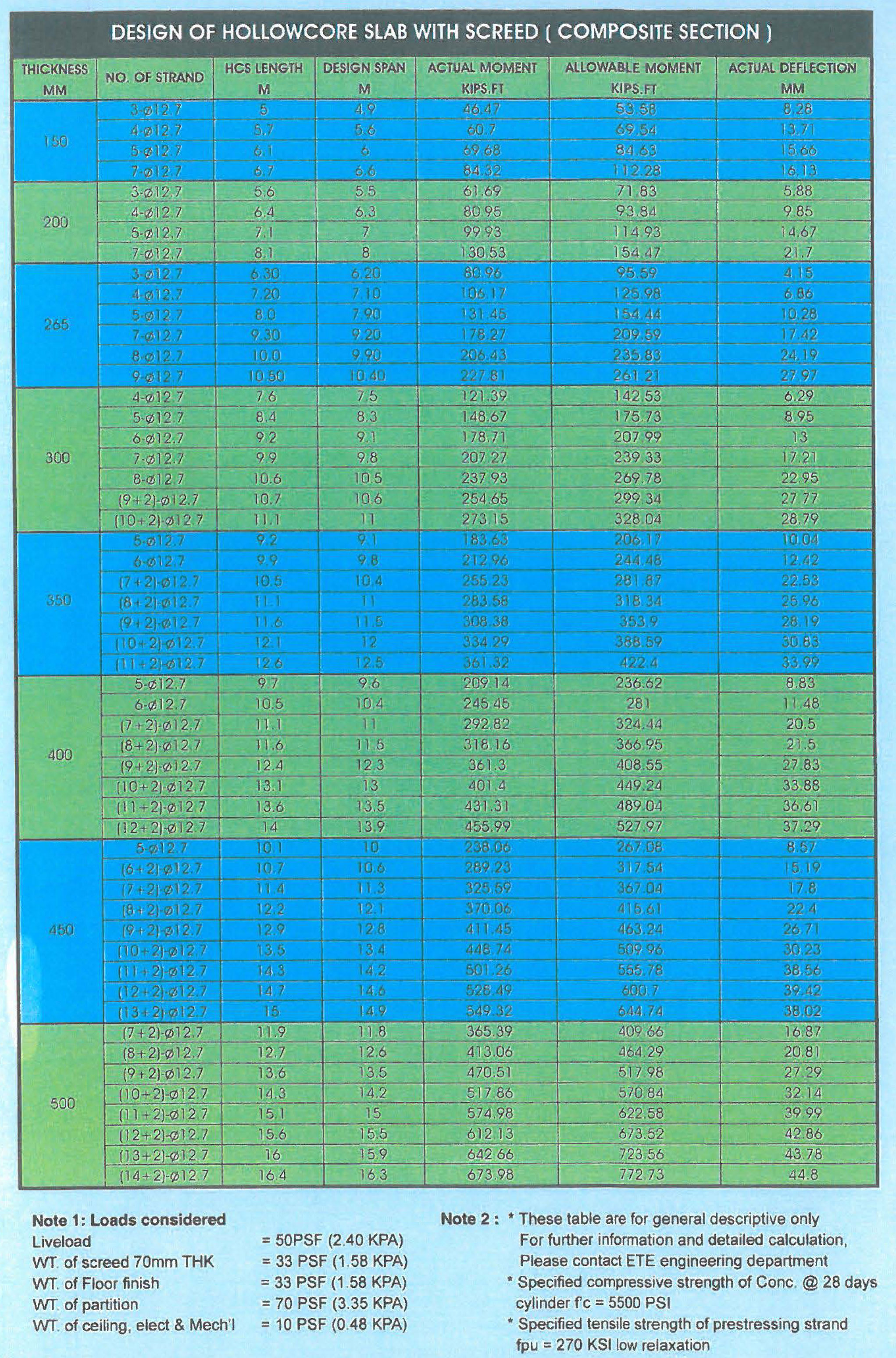

A hollowcore slab is a precast, prestressed concrete member

with continuous voids provided to reduce weight and, therefore,

cost and, as a side benefit, to use for concealed electrical or

mechanical runs. Primarily use as floor or roof deck systems,

hollowcore slabs also have applications as wall panels, spandrel

members and bridge deck units.

An understanding of the methods used to manufacture

hollowcore slabs will aid in the special considerations sometimes

required in the use of hollowcore slabs. Hollowcore slabs are cast

using various methods in the seven major systems available

today. Because each production system is patented, producers

are usually set up on a franchise or license basis using the

background, knowledge and expertise provided with the machine

development. Each producer then has the technical support of a

large network of associated producers.

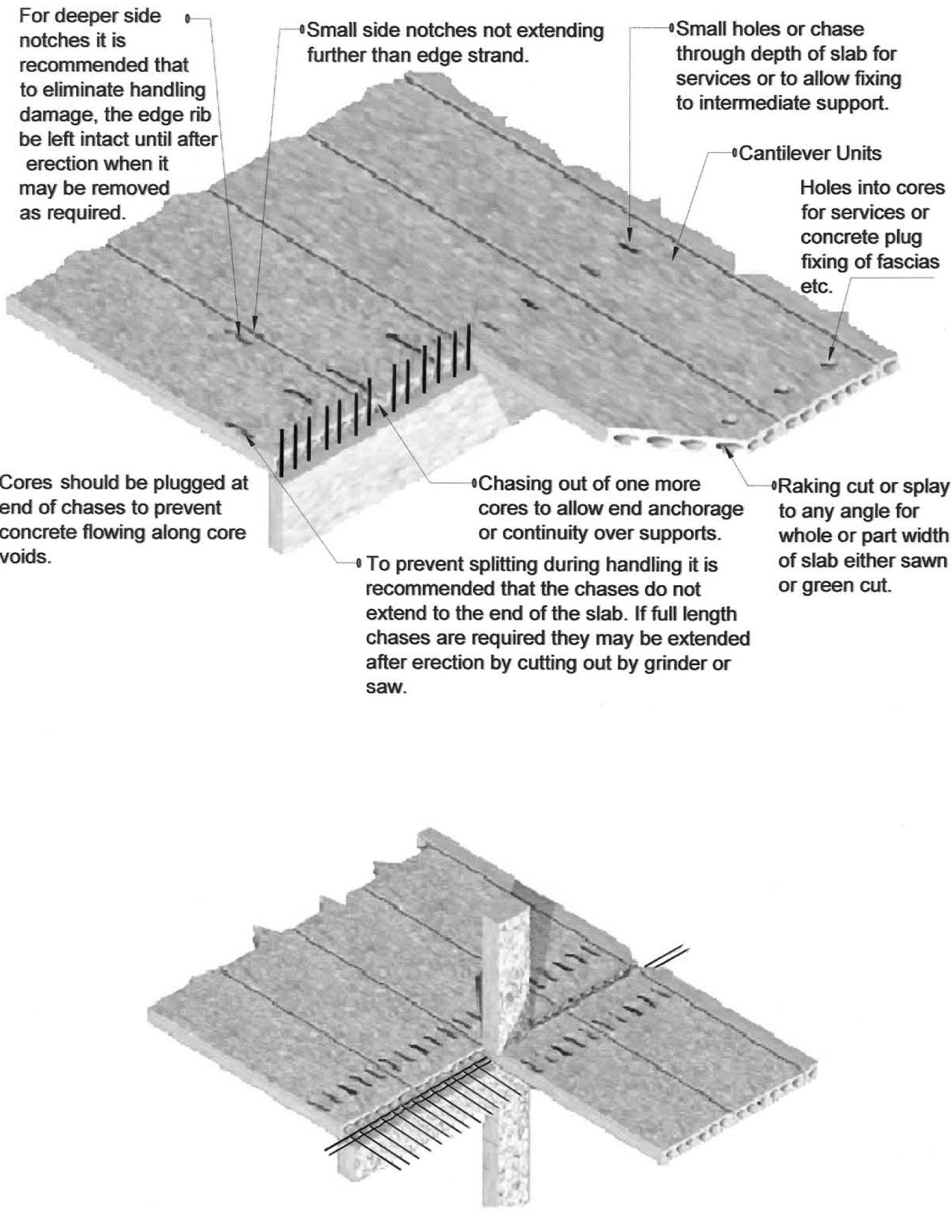

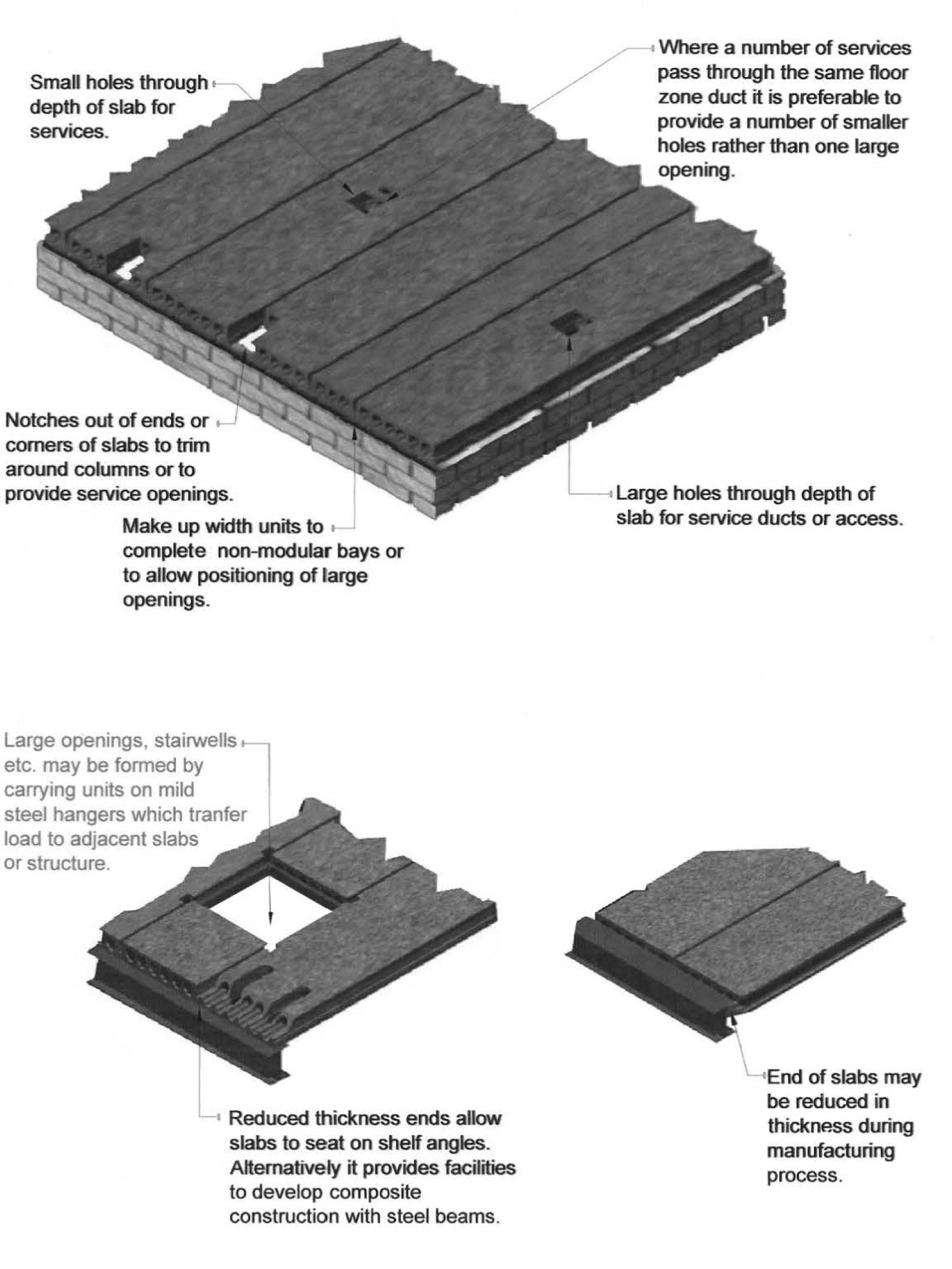

Special Applications to suit requirements & strength of units.

OTHER BUILDING SYSTEMS

EPC building systems comprises an extensive range of complimentary precast

concrete products which have been developed and established over several

years. They are based on technically proven, high quality cost effective building

systems used extensively in the construction industry throughout.

All EPC building systems products are designed, manufactured and erected to

meet current local, international, Saudi Aramco and Saudi Electricity Company

material standard specifications. They can also be designed and standardized

to interface with client designs and site requirements to provide a quality

precast building systems with maximum speed and flexibility to meet most

applications.

The numerous structural products and system include the following:

1. Building frames cladding structures suitable for industrial units, schools,

housing and commercial building

2. Carpark multi storey structures and cladding

3. Housing systems

4. Carpark shed frames and claddings

5. Mosque and minaret structures and features

6. Boundary wall system

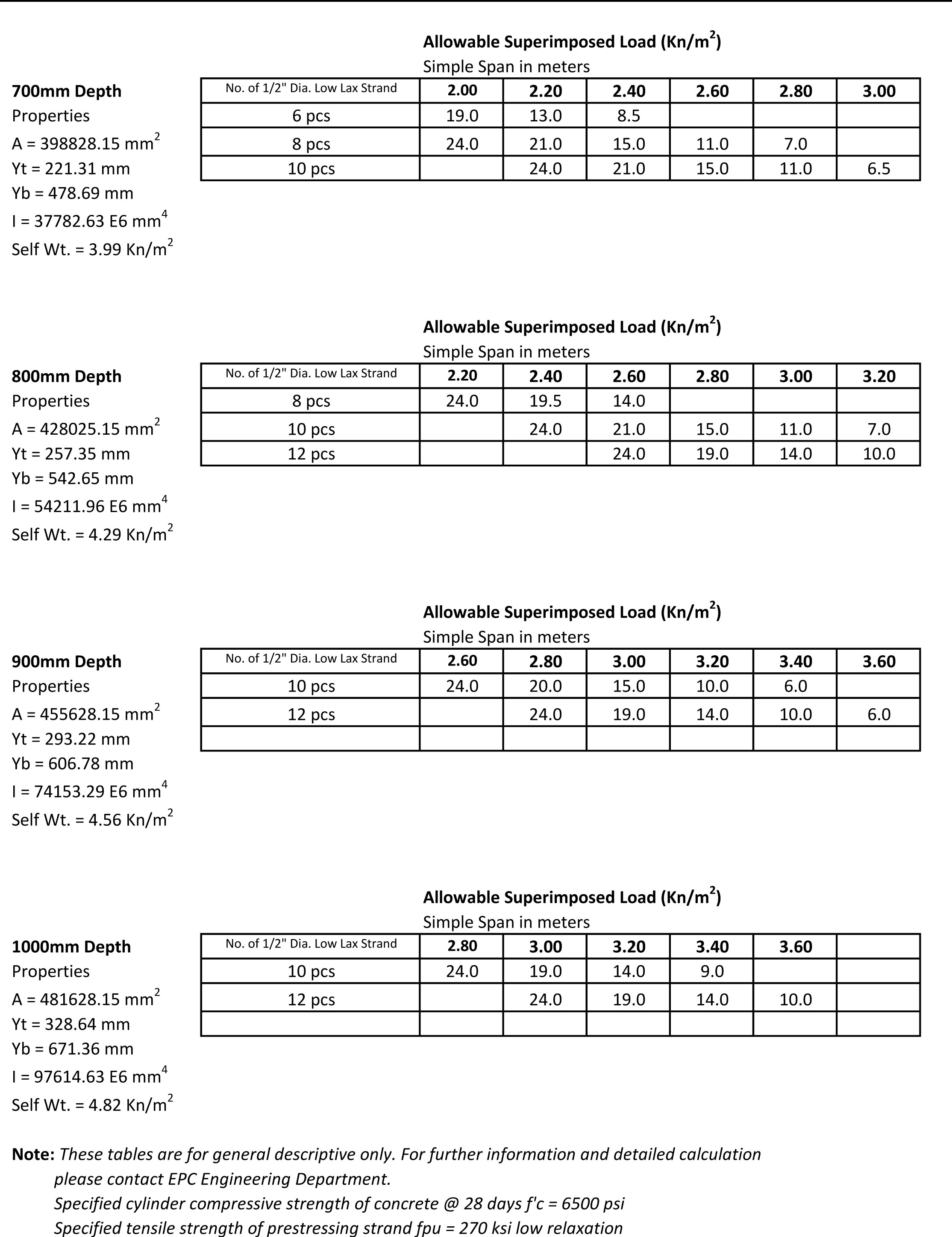

7. Prestressed hollowcore slab and wall product

8. Precast Column and beam frame

All EPC products are designed, manufactured and erected to meet with clients,

architects, and engineers functional loading and dimensional requirements and

to EPC quality assurance and prevailing international and local Saudi Aramco

standards and Saudi Electricity Company material standard specifications.

EPC are always available for consultation on all technical matters, project

feasibility and proposals from clients, consultants and contractors.

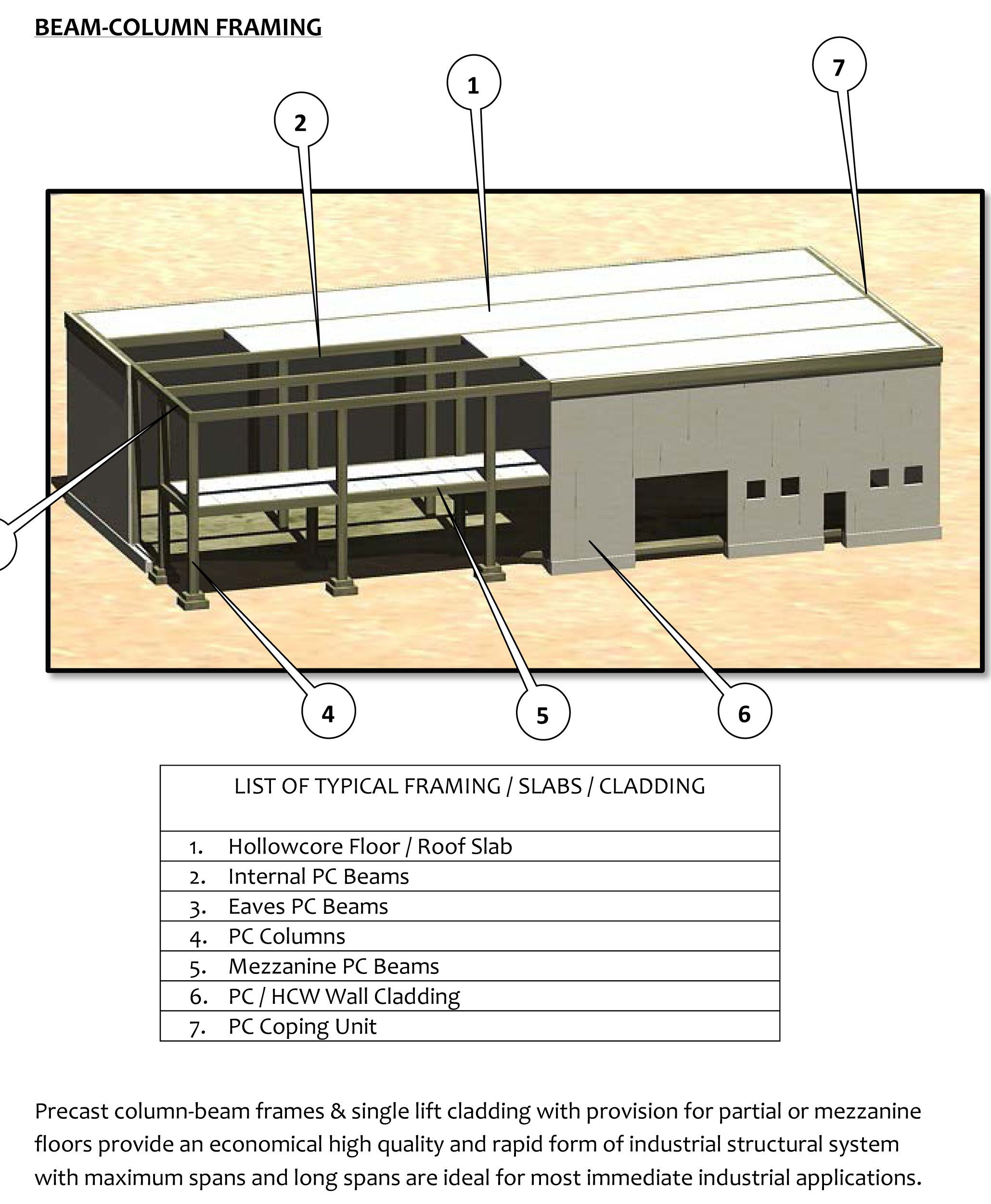

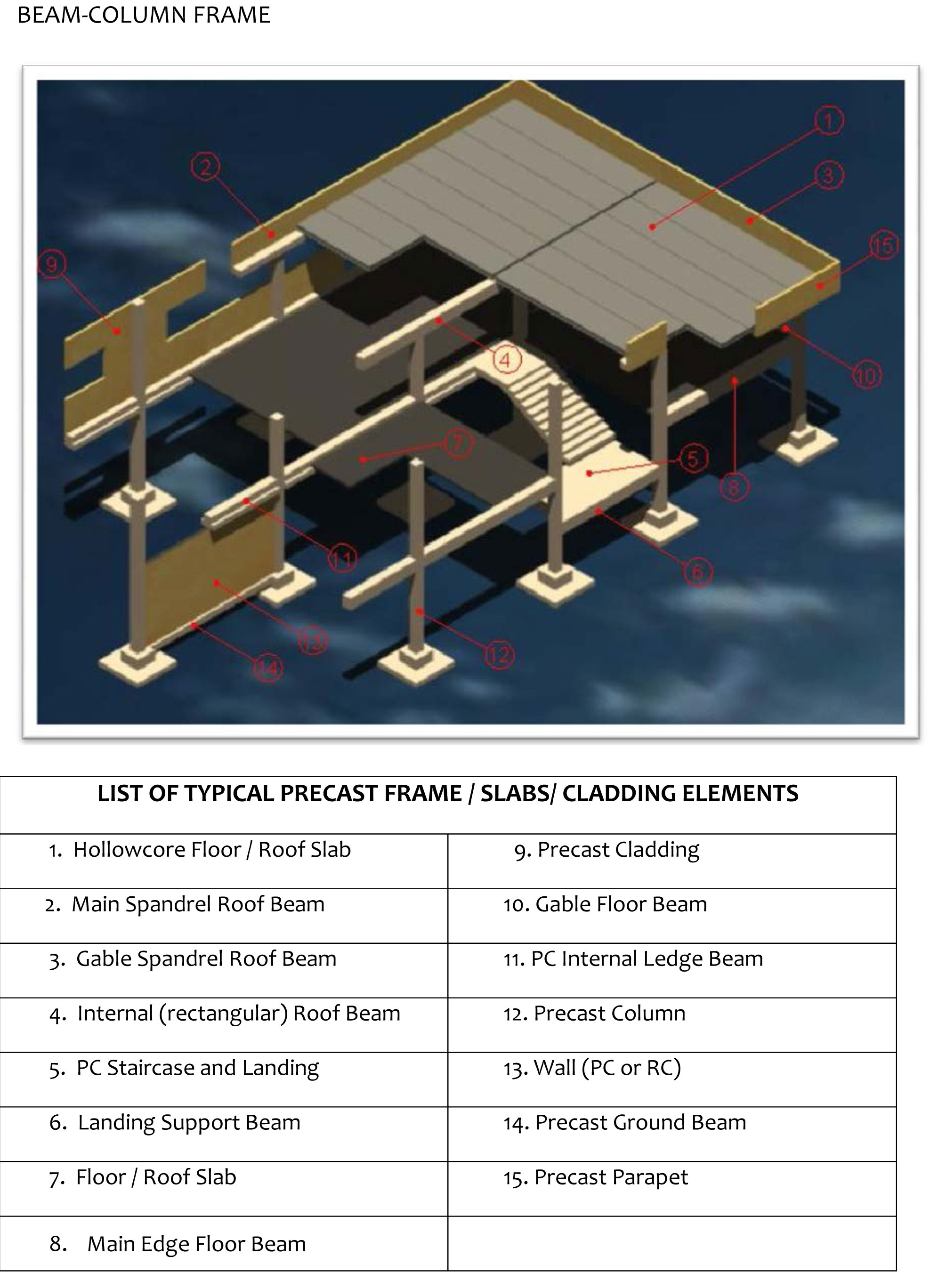

INDUSTRIAL FRAMING, CLADDING &

STRUCTURAL SYSTEM

Precast column-beam frames and cladding with floor and roof components can be used in a

variety of single and multi storey buildings for industrial, warehousing, commercial,

recreational and institutional applications. Durable, fire resistant and quickly erected, these

structures can be framed in long clear or short spans and provides maximum flexibility for

interior space planning. Provisions for such special features as roof openings and suspended

superimposed loads are readily engineered into the design.

LIST OF TYPICAL PRECAST FRAME / SLABS / CLADDING ELEMENTS

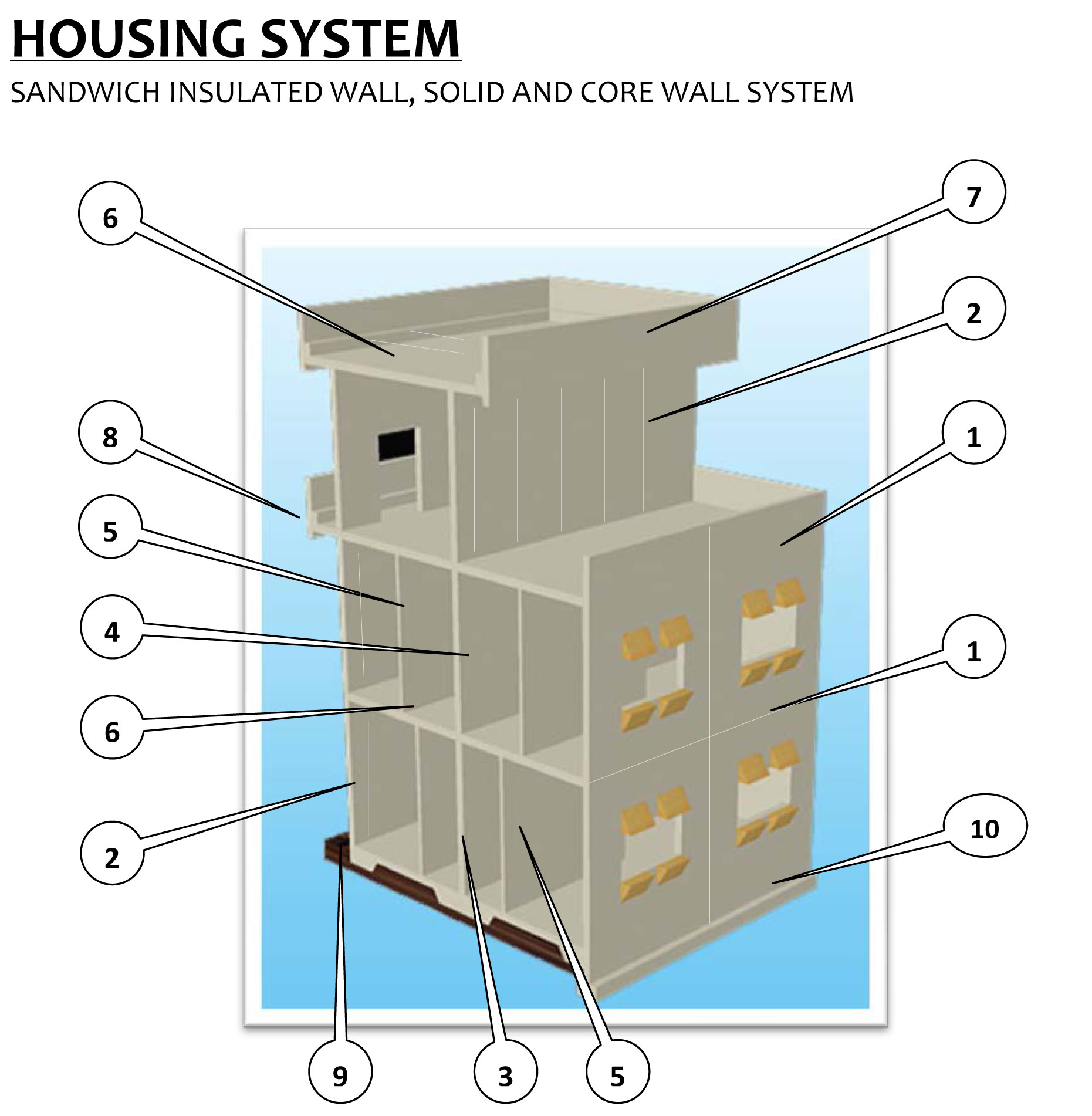

1. External insulated Load Bearing Wall Panel

2. External Core Load Bearing Wall Panel (w/ or w/o finish)

3. Internal HC Load Bearing Wall Panel

4. Internal Solid Load Bearing Wall Panel

5. Internal Non-Load Bearing Wall Panel

6. Hollowcore Floor / Roof Slab

7. Precast Parapet

8. Balcony Slab

9. CIP Raft Foundation

10. CIP Strip Foundation

Sandwich, Solid and Core Wall Systems provide a flexible and rapid Architectural and Preengineered

Housing System. It provides economical high quality solution to the housing

needs of the Middle East Countries.

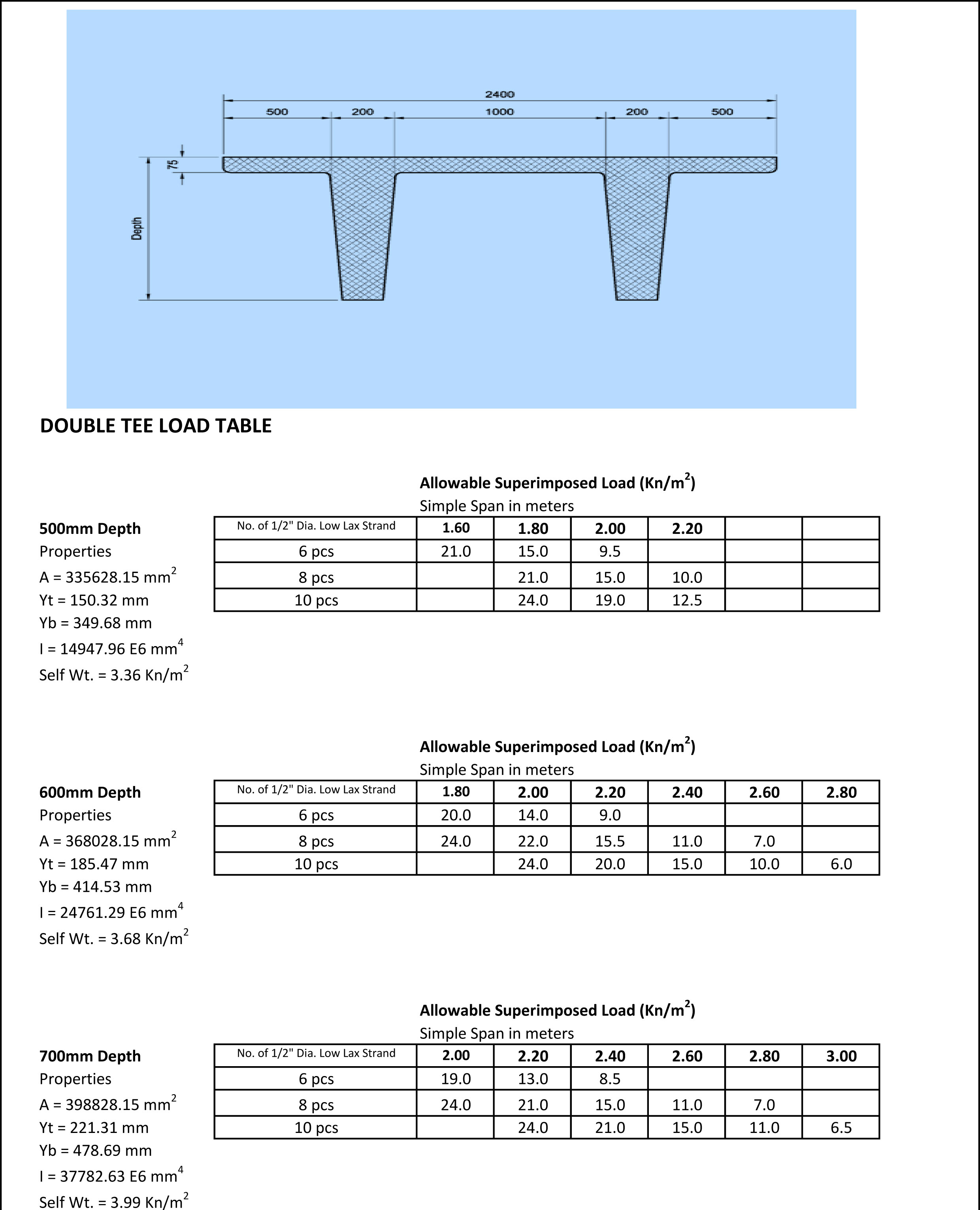

PRES-STRESSED DOUBLE TEE SLAB

Double Tees mostly floor deck and roof deck components for any type of

structures.

Flange thickness 75mm

Typical Width 2.4 m

Typical Depths 500m, 600m, 710m, 800m, 900m, 1000m, 1075m

Typical span-to-depth ratios: Floor or Roof 11m to 25m

Manufacturing Method:

Casted in 2 – 150 m long pre-stressing beds that are subdivided into specific

length tees as required by the project. Production consist of:

Laying out forms

Stressing the strands

Installing embedded materials and reinforcement

Pre-pour Quality Check

Casting proper

Curing

Detensioning or releasing of strands

Stripping

Post-pour Quality Check

Stocking and wet curing