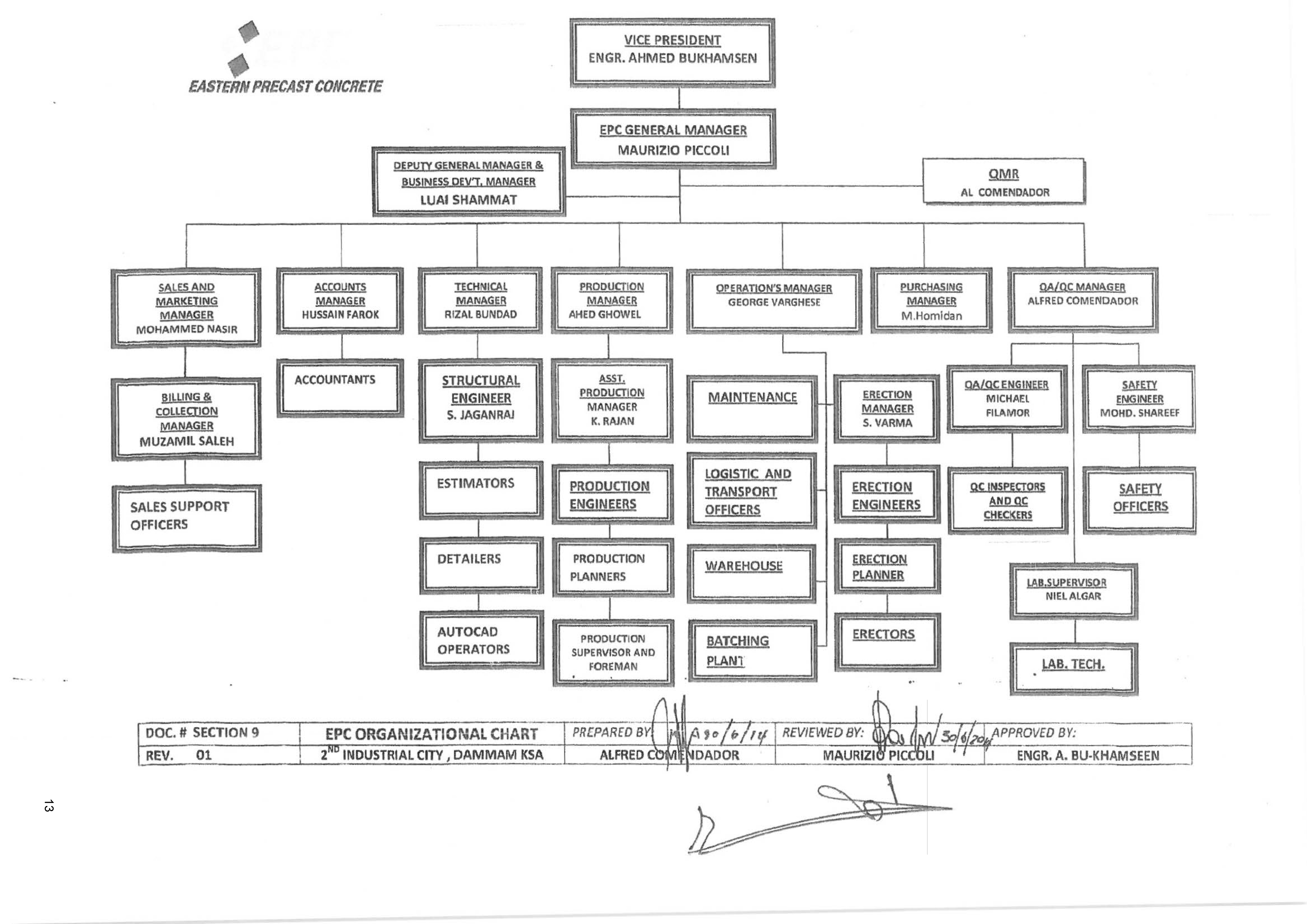

Organizational Chart

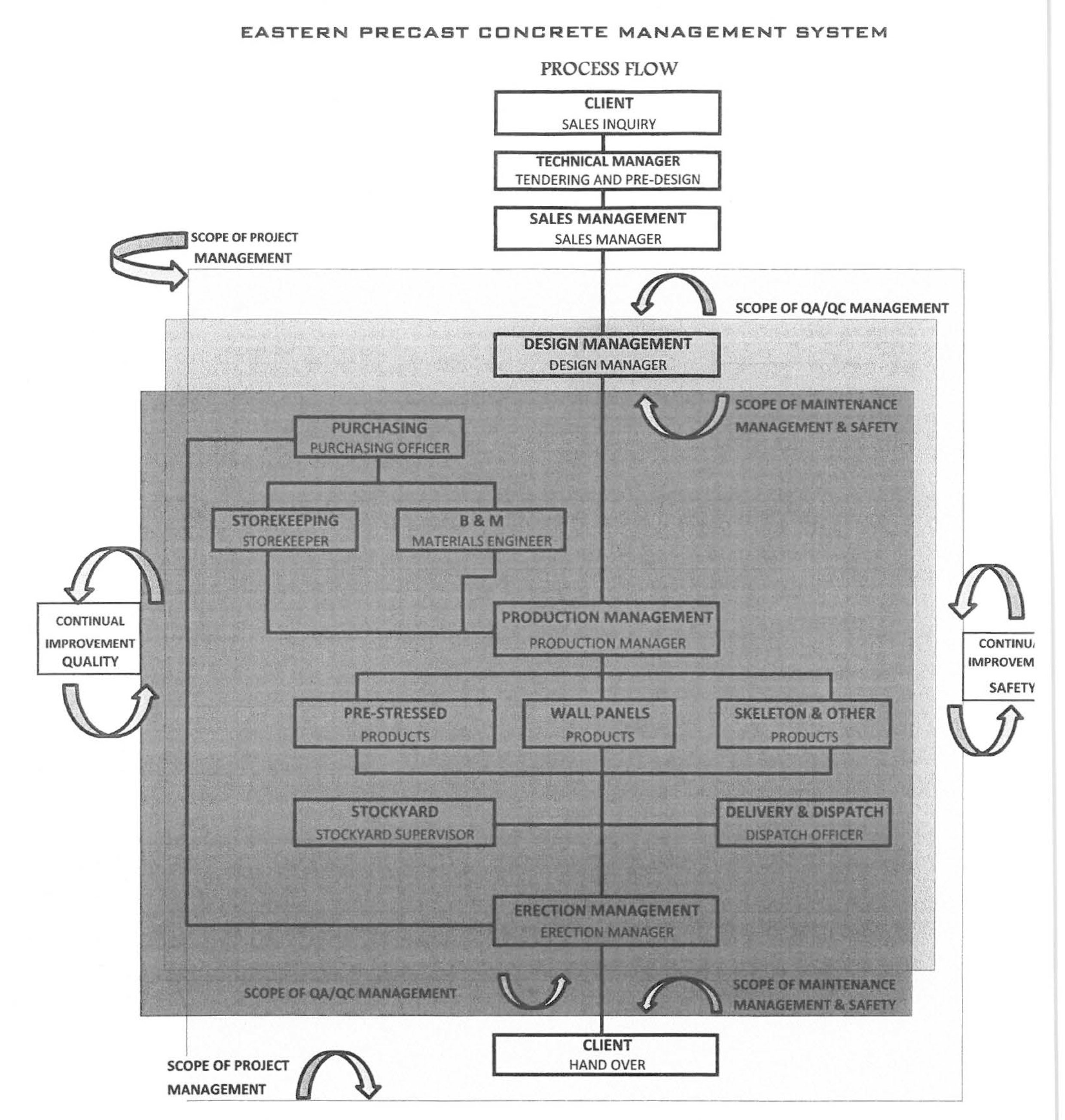

Sales, Design, Production and Erection Procedures are collectively called

DIRECTIONAL PROCEDURES.

Project Management, OA/QC, Maintenance ansd Safety Procedure are

collectively called BLANKET PROCEDURES.

Purchasing, Storekeeping, Batching &Mixing, Stockyard, Dispatch & Delivery

Procedures are collectively called SUPPORT PROCEDURES

Administration and Finance Management are collectively called SUPPORT

DEPARTMENTS.

EPC CHANGES AND DEVELOPMENT as of 2014

1. New General Manager- Engr. Maurizio Piccoli

2. New Engineering and Technical Manager- Engr. Rizal Bondad with 14 existing personnel

and 6 additional personnel including 2 structural Engineers.

3. New Erection Management

Erection Manager: Mr. Subrahmanyam Varma,

Erection Engineer: Engr. Rey Uson

Project Coordination: Mr. Manish Kumar

4. New QA/QC Engineer- Michael Filamor and additional 2 QC Inspector

5. New Expansion Stockyard at 52,000 m2 land area

6. 650 Manpower under EPC sponsorship

7. Additional double Tee(108mtrs. length)

8. New Batching Plant full operational Model: GPE 120 (German) Capacity: 4.0mJ I batch

9. Pre-Stressed Beam- 0 Type and L type(100mtrs length)

10. Wet or water curing using sprinkler at stockyard

11. Additional 25 new trailers

12. Additional overhead cranes(G cranes)

13. Sand Blast Machine (3 additional)

14. Welding Machine (25 additional)

15. New Bar Cutting and Bending Machine ( Focus 12 MEP)

16. Additional covered Production building- 40 Tilting tables Target Date of Completion

September 2014.

17. Expansion of warehouse (300 m2)